30+ YEARS OF EXPERIENCE

ELCON d.o.o. was established in 1990. We started as a system Integrator Company focusing on different fields of productions. From the very beginning we have been using control equipment from the world leader in industrial control system; SIEMENS.

Our company is Certified Solution partner for PCS7, SIMATIC and WinCC system from SIEMENS. We are active in various fields of industry including Chemical, Oil and Gas, Pulp&Paper, Cement and Refractories.

Our solutions range from design and engineering to programming of control and supervision system. We supply also complete electrical package.

ELCON employs electrical designers and programmers. Smaller projects are carried out by our own engineers, while larger ones are subcontracted out and we take over the project management.

Project procedure

Requirements analysis

Reviewing project input data; including technical meetings, P&I diagrams, functional expectations and client process requirements.

Project documentation

Preparation of basic and detailed design documentation, including functional descriptions, design specifications, and other technical documents.

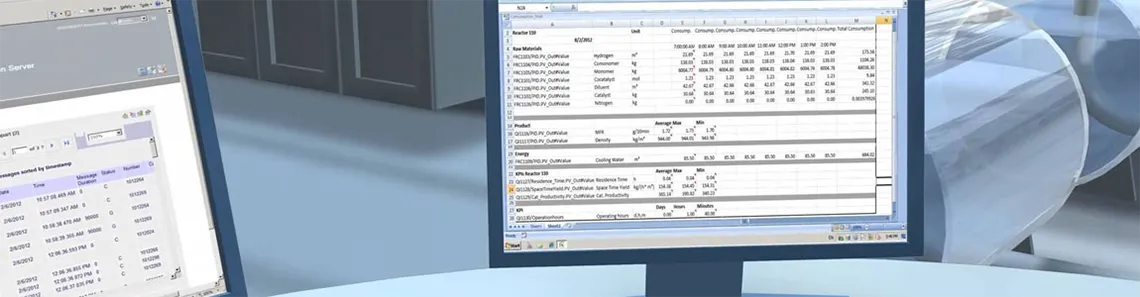

Electrical design and software development

Complete electrical design and development of software logic, including PLC, HMI and SCADA programming according to approved specifications.

Cabinet assembly

Assembly of the electrical cabinet, installation of all components, wiring and labeling.

Testing of cabinets and software

Execution of FAT, testing of the electrical cabinet and control program using a digital twin.

Installation and technical acceptance

Installation of equipment, commissioning, SAT (Site Acceptance Test), operator training and final project handover.

After-sales support and upgrades

Post-delivery technical support, troubleshooting, maintenance services and implementation of future upgrades or system improvements.

COMPANY’S FACES

OUR TESTIMONIALS

engineers

countries

projects

COMPANY INFORMATION

Company name ELCON podjetje za avtomatizacijo, razvoj in inženiring d.o.o.

Short company name ELCON d.o.o.

Company headquarters Ljubljanska cesta 80, 1230 Domžale, Slovenia

Year of establishment 1990

Number of employees 12

Company registration number 5405556

Identification number SI28367014

Taxpayer YES

Business account SI56 0400 0027 6589 621

SWIFT code KBMASI2X